Home

Feedback

Sign In

EN

- 中文

Preview mode

Oil&Gas Information

You can access comprehensive oil&gas industry information from the oil&gas knowledge section, including technology trends, news, reports, and business opportunities. The platform uses AI to provide an intelligent and personalized user experience, serving as your smart assistant.

Oil&Gas Exposition

Oil&gas exposition provides online promotion and display services for products/services for global oil and gas industry enterprises,quickly builds an online product display platform,utilizes Anton's industry influence, brings huge client traffic and brand push influence for your enterprise, realizes online attraction, and promotes offline transactions.

Oil&Gas JobAI

Oil&Gas JobAI is a professional talent search and recruitment platform for the global oil and gas industry, linking enterprises and job seekers, quickly building online job posting and recruitment platforms for enterprises, providing accurate job matching for job seekers, integrating AI resume optimization and online communication and other functions, providing excellent online experience for supply and demand sides.

Engineering Scheme Design GPTs

Utilizing AI models to devise scientifically feasible engineering design scheme that integrate geological conditions, production targets, and engineering requirements and other factors in the target area;

Geological Analysis GPTs

Leveraging AI models for geological interpretation in oil&gas development, assisting field personnel in real-time understanding of reservoir conditions and operations, providing decision support for development;

Production Process Optimization GPTs

Optimizing production processes with AI models to enhance development efficiency, reduce risk losses, and ensure the safe and stable development of oil&gas fields;

Intelligent Engineering Scheme Assists Design Model

Intelligent Engineering Scheme Assists Design Model uses text analysis technology to integrate data from neighboring wells and engineering plans from the same platform, extracting key information to generate a standardized design document template. The model can provide optimization suggestions based on analysis results, assisting in quickly establishing a basic engineering plan. It features automated design writing capabilities, simplifying the design process, reducing manual operations, and enhancing design efficiency.

Fracking Design Scheme Parameters Optimization Model

Fracking Design Scheme Parameters Optimization Model, according to the actual drilling trajectory of the new well and the stacking and contact relationship of different river sands, the AI model is used to assist in the formulation of personalized schemes, optimize the segmentation and clustering parameters, and maximize the fracture control volume and release the effective sand production capacity. Meanwhile, the bottomhole pressure and net pressure are calculated in real time, and based on the change of net pressure, the fracture extension is judged in time, the risk of sand plugging is pre-determined, and the construction parameters are optimized and adjusted in real time to ensure the maximum fracture-control volume of a single well.

Oil & Gas Field Development Design Model

AI models craft detailed oil and gas field development plans, covering extraction methods, production facilities, and process design. The goal is to optimize resource development efficiency while ensuring safety and environmental protection.

Fiber Optic Wellbore Leakage Point Real-time Prediction Model

Real-time fiber optic wellbore leak detection model leverages AI to analyze geological layering information in real-time, automatically generating alerts to assist engineers in adjusting drilling parameters promptly.

You can clean and organize fiber optic detection data, and utilize the model to display this data on the front-end interface through DAS and DTS heat maps, showing real-time changes in various wellbore parameters. These heat maps not only reflect the operational status of the wellbore in real-time but also support zooming, dragging, and viewing detailed data at specific depths and time intervals.

DAS Leak Detection:

By inputting real-time data from fiber optic sensors into a pre-trained linear regression model, you can achieve real-time prediction of wellbore conditions. This prediction effectively monitors changes in various parameters within the wellbore, promptly identifying potential leaks or other anomalies. The model is transparent and easily interpretable, allowing business personnel and decision-makers to understand and optimize adjustments intuitively.

Reservoir / Lithology Identification

Oil & Gas reservoir is a rocky area where Oil & Gas collect underground in Oil & Gas exploration engineering. Reservoir characteristics include lithology, physical properties, and hydrocarbon content, which is the main direction of reservoir prediction. Reservoir lithology is the main feature that describes the mineral composition of the reservoir, reflecting the storage performance and reservoir characteristics of the formation, and the commonly used parameters include the physical structure of the reservoir rock, the distribution range, the tectonic morphology of the top interface of the reservoir, and the thickness of the reservoir. Comprehensive reservoir characteristics can realize the prediction of Oil & Gas rich area, i.e. sweet spot, and indicate the location and exploitation plan for Oil & Gas drilling.

Equipment Intelligent Monitoring

Through the online monitoring system, the operating status data of the well dressing machine can be monitored in real time. This real-time not only provides technical support for the field operators, but also enables the oilfield managers at all levels to understand the status of the production site in a timely manner, thus providing a basis for decision-making.

Geological /Engineering Sweet Spot Identification

In the process of Oil & Gas exploration and development, large Oil & Gas areas and large segments of Oil & Gas layers will be revealed, but often some of them have better development benefits under the current economic and technological conditions.

Dynamic Evaluation Of Artificial Fracture Reforming Volume

Based on the actual natural fracture response, stress, and brittleness of each section of wells on various platforms; carry out a comprehensive comparative assessment of the qualitative and quantitative descriptions of the complexity of artificial fractures and the extent of pressure interference.

Fiber-optic Liquid-producing Profile And Gas-producing Profile Monitoring

Fiber optic production profile testing technology realizes fiber optic distributed monitoring by pumping armored fiber optic cables into the continuous tubing in advance, and then transmitting the continuous tubing to the destination test layer through the continuous tubing vehicle group during operation.

Dynamic Monitoring Of Fracturing Sand And Fluid Intake

Fiber optic fracturing monitoring technology primarily utilizes distributed acoustic sensing (DAS) and distributed strain sensing (DSS) technologies with deployed optical fibers in the same well or neighboring wells for monitoring. Through in-well DAS monitoring, it visually displays the fluid and proppant intake of each cluster, guiding the optimization of fracture diversion and reservoir stimulation. Real-time monitoring of low-frequency strain signals depicts the development and status of fracturing cracks, guiding the fracturing process in real-time. Extracting microseismic signal events assesses the effectiveness of fracturing and optimizes the fracturing plan.

Intelligent Analysis Of Geological Stratification Model

Intelligent Analysis Of Geological Stratification Model,You can utilize an AI model to analyze geological stratification information in real-time, automatically generate early warning messages, and assist engineering personnel in adjusting drilling parameters promptly. This provides precise geological guidance suggestions for the drilling process, thereby significantly enhancing the efficiency and safety of drilling operations.

The AI model integrates MWD (Measurement While Drilling) and LWD (Logging While Drilling) data to analyze geological stratification in real-time, offering accurate geological guidance for the drilling process. It also automatically generates alerts and alarms based on preset thresholds, ensuring that engineering personnel can adjust drilling parameters in time to avoid risks. Moreover, the model provides decision support for geological stratification prediction and optimization of drilling parameters through in-depth analysis of historical and real-time data, thereby significantly enhancing the efficiency and safety of drilling operations.

Intelligent Prediction Of Estimated Ultimate Recovery (EUR) Model

Based on the Intelligent Prediction Of Estimated Ultimate Recovery (EUR) Model,the following tasks can be carried out:

Intelligent prediction of estimated ultimate recovery (EUR), and correlation analysis of engineering and geological parameters affecting fracturing.

This model utilizes advanced deep learning technology to analyze engineering and geological parameters related to fractured EUR prediction, accurately analyzing the impact of different parameters on the final recoverable reserves, thereby guiding adjustments in the construction process.

By employing machine learning techniques, the model deeply mines the parameters affecting EUR, revealing the connections between different parameters and EUR, thus providing users with EUR analysis.

Drilling Construction Parameter Generation Model

You can utilize Drilling Construction Parameter Generation AI Model to obtain suitable adjustable parameters such as drilling pressure, drilling speed, and pump pressure. During drilling operations, based on the input well depth and basic properties of the drilling tools, as well as the physical and chemical properties of the drilling fluid, such as cylinder diameter and mud density, the model can accurately recommend suitable adjustable parameters like drilling pressure, rotation speed, and pump pressure.

By leveraging drilling design and tool characteristic analysis, customized settings for drilling parameters are achieved. Users can manually adjust the thresholds for key indicators such as drilling pressure and rotation speed to ensure that each drilling operation meets the precise requirements of specific regions and geological conditions. By accurately recommending suitable combinations of drilling parameters, the model maximizes drilling efficiency, reduces energy consumption and costs, and achieves efficient and stable drilling. Regarding the optimization of engineering parameters:

Formation Pressure Anomaly Alarm Model

Formation Pressure Anomaly Alarm Model helps you accurately predict the formation pressure and detect drilling abnormalities in time; through real-time monitoring of key parameters in the drilling process, the system can quickly calculate the formation's DC index, which is the formation's drillability index, and identify abnormal fluctuations or over-threshold situations in time through the machine learning model. Timely pressure warning helps to detect abnormal pressure at an early stage, achieve early detection and early disposal, and help to realize well control safety.

Intelligent Sand Plugging Alarm Model

You can utilize an Intelligent Sand Plugging Alarm Model to dynamically monitor and predict sand plugging risks. This model aids in the intelligent transformation of sand plugging management, providing comprehensive solutions for sand plugging issues in oil and gas extraction. The system employs deep learning algorithms for sand plugging risk assessment, efficiently handling complex data patterns for precise prediction and real-time analysis. The model uses advanced data processing technologies and edge computing to ensure the efficiency and reliability of data collection, transmission, and real-time processing. The speed of data processing and analysis is significantly improved, ensuring timely identification and feedback of sand plugging risks. The model is designed with a modular architecture, supporting flexible expansion based on user needs and actual application scenarios. Whether adding new sensor types or integrating additional analysis functions, the model can easily adapt to provide customized sand plugging risk management solutions, enhancing the accuracy of early warnings and response speed.

Intelligent Injection And Recovery Decision-making

To enhance waterflooding efficiency, personnel need to integrate intelligent layer-by-layer water injection systems with intelligent layer-by-layer oil extraction systems. By linking injection and production, they can monitor the water injection and oil extraction in real-time, dynamically compare and analyze the water injection volume, liquid production, water cut, and pressure of each layer, enhancing the targeting and flexibility of reservoir control and increasing the implementation rate of water injection plans.

Oil & Gas Field Video Surveillance

Real-time capture, intelligent identification, and proactive early warning of violations on oil&gas fields significantly save supervisory human resources and enhance the quality and efficiency of regulation, effectively preventing safety risks.

Artificial Lift Optimization

The role of artificial lift is to extract Oil & Gas to the surface, which is an important part in crude oil extraction. Differences in oil wells in terms of well structure, production, and fluid properties promote the diversification of artificial lift technology.

Intelligent Control Of Machine Mining

Achieve comprehensive control over the operation and energy consumption of Rare well extractors by leveraging IoT data, combined with big data technology, condition diagnosis technology, and enhanced oil recovery optimization techniques to deeply mine the potential value of massive data sets.

Optimization Of Energy Consumption In Oil & Gas Fields

Promoting energy saving and consumption reduction in the four major production systems of machine mining, water injection, gathering and transportation, and electric power, and promoting the improvement of quality and efficiency. Through “shutting down, stopping, merging, transferring and reducing”, as well as measures such as wellbore process optimization, balancing of machine mining wells and opening of low-producing wells, the company realizes power saving in the machine mining system, and implements measures such as reducing the capacity of power distribution in the electric power system and replacing energy-saving electric motors, so as to save electric power consumption.

Production Scheduling Strategy Optimization

Utilizing AI technology for intelligent operation scheduling can greatly enhance the efficiency and safety of oilfield operations. AI models can analyze geological strata in real-time, automatically generate early warning messages, and assist engineers in adjusting drilling parameters promptly. This technology helps in planning the various tasks of oilfield enterprises, ensuring orderly and efficient production and construction processes.

Active Early Warning Of Equipment Failure

Utilizing AI models to analyze the working conditions of equipment, predict equipment failures, and issue timely alarms can help avoid work stoppages and extended maintenance periods caused by equipment malfunctions.

Enterprise Management Knowledge GPT Development Services

Provide GPT development services for internal operations management administration for your organization. Such as the use of artificial intelligence big language modeling technology, your enterprise's system, knowledge and other model training, easy for employees to quickly find the knowledge of various areas of the enterprise.

Enterprise Management Digital Intelligence Overall Solution Services

Provide your company with business-based management system digital intelligence architecture consulting, design, and planning, assisting clients in planning key projects and designing solutions. Taking the core business and management support processes as the main thread, build full online operation management through the platform, and enhance operational efficiency through intelligent means.

Data-driven Intelligent Decision-making Platform Design and Construction Services

Integrate your enterprise's business systems to provide integrated data governance and data query services.

Construct data service maps for personnel in various positions, which can query enterprise operation and management data in the form of real-time visualization, AI dialogue, etc., warn operation and management risks in advance, and improve enterprise operation and management efficiency.

Data Visualization Architecture Design

Data center and architecture planning

Data governance and system improvement

Data-driven project management and implementation

Smart Employee Community Design and Construction Services

Intelligently manage your online communities, such as DingTalk and WeChat Work for businesses, helping employees use various AI-powered office tools to increase organizational efficiency.

Community Building Solutions Design

Community Building Resource Organization

Community Building Project Management and Implementation

Community Data and Configuration Initialization

Training for Users of All Roles

Community Launch and Promotion

Community Operation and Maintenance, Optimization

Smart E-commerce Platform Design, Construction and Operation Services

Build an intelligent external e-commerce platform for your enterprise to support online brand and product promotion.

Intelligent e-commerce platform demand research

Planning and construction of intelligent e-commerce platform

Project management and implementation of intelligent e-commerce platform construction

SEO promotion and optimization of intelligent e-commerce platform

Intelligent e-commerce platform traffic analysis, operation and maintenance services

Management Process Automation Platform Design and Construction Services

Provide intelligent process processing, automatic identification and other services for your business.

Through the process of automatic robot RPA, graphic recognition OCR, Python and other intelligent tools and languages, to achieve the rules-based process system, 24 hours a day, automatic identification and verification, automatic processing processes, significantly reduce manual operation, improve process efficiency.

OpenAI

OpenAI is an AI development company, officially established in 2015 by eight leaders including Elon Musk. It is a comprehensive platform that integrates AI model development, API services, research and innovation, education and training, and community support. It provides people with opportunities to understand and learn AI technology, and also promotes the development and application of AI technology.

ChatGLM

The first generative AI assistant launched by Beijing Zhi Spectrum Huazhang Technology Co., Ltd, which is based on Zhi Spectrum AI's self-developed Chinese-English bilingual dialogue model ChatGLM2, and has been pre-trained with trillions of characters of text and code, to provide intelligent services for users.

MURF.AI

MURF.AI is a powerful, user-friendly, and privacy-focused text-to-speech platform dedicated to revolutionizing media production through AI technology. It offers features such as text-to-voice conversion and AI voice generation, suitable for a variety of scenarios and needs.

Midjourney

Midjourney is an innovative AI art generation platform that offers AI art creation, a variety of artistic styles, and interactive creation features. With its unique AI art creation capabilities and diverse artistic styles, it provides users with a brand-new creative experience and communication space.

Lumen5

Lumen5 is a video creation platform powered by AI that enables anyone without training or experience to easily create engaging video content within minutes that offers features such as text-to-video conversion, automated video editing, content personalization, and brand customization.

Flair.ai

Flair.ai is an AI design tool website that provides a powerful AI design tool aimed at simplifying the process of product photography, increasing work efficiency, and providing users with high-quality, diverse product photos. With real-time collaboration and intelligent design, this tool meets the diverse needs of teams and individuals.

Gamma

Gamma is a website that uses AI to create presentations and slides without the need for design or coding skills. It allows users to create an unlimited number of beautifully designed presentations, documents, websites, and more, all within seconds. The website boasts advantages such as on-demand assistance, seamless integration/easy output, and ease of sharing and publishing.

Scholarcy

Scholarcy is a powerful academic tool that helps users summarize, analyze, and organize research content. It is suitable for students and researchers from undergraduate to postgraduate levels and beyond. The tool offers features such as text summarization, text analysis, knowledge management, and cross-platform applications.

CURSOR

Cursor AI is a code editor that stands out for its robust features, user-friendly interface, and continuous technological updates. Leveraging advanced AI technology, it offers intelligent code completion suggestions to help developers write code quickly. It also detects errors in the code in real-time and provides suggestions for corrections, enhancing code quality and development efficiency.

runway

Runway is a platform that integrates a variety of AI creative tools, designed to inspire and support human creativity. It enables the online generation of AI videos and features such as text-to-video, image-to-video, and more. Runway is widely used in fields like video production, e-commerce videos, and advertising promos.

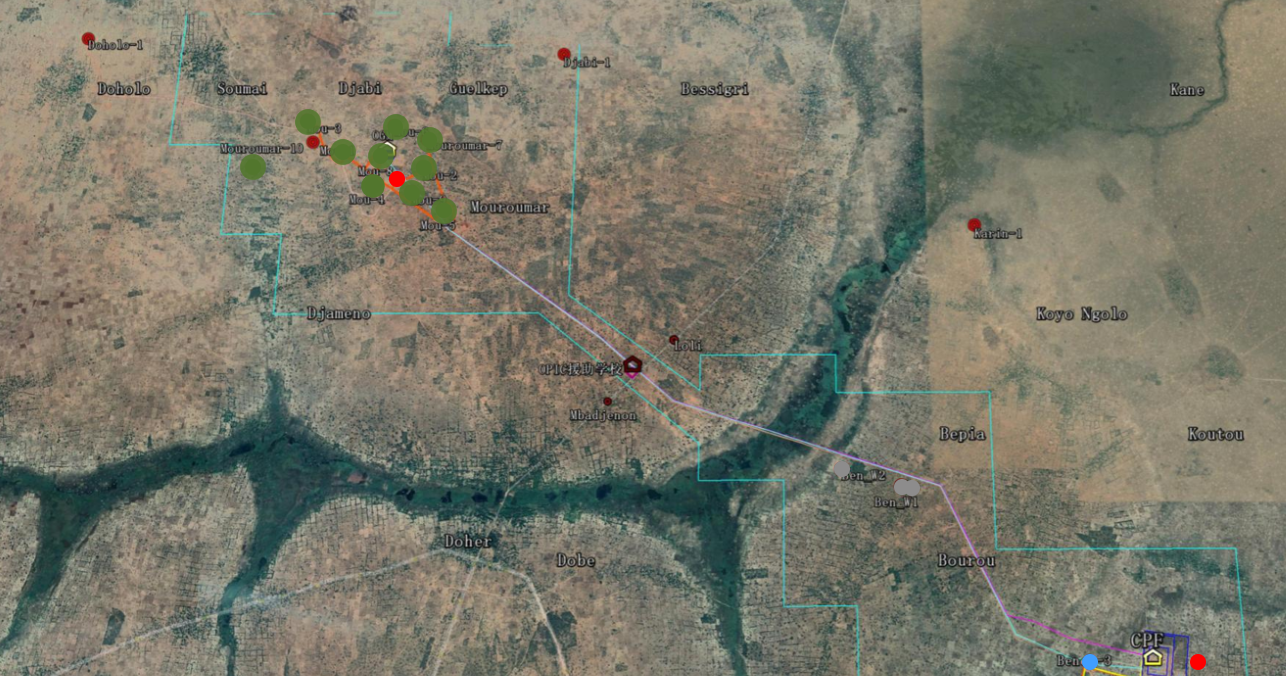

Reservoir Geology Evaluation

Facing the whole bureau, focusing on single-well reservoir geological fine research, featuring the combination of geological engineering, providing you with comprehensive geological research and evaluation, development plan preparation services, and at the same time, providing geological risk evaluation services for the overall solution of Andong.

Seismic Phase Recognition

Machine learning and deep learning for data preprocessing, feature extraction, MCC calculation, model training, and seismic phase classification.

Deep Learning Logging Petrographic Recognition

Automatic identification and classification of logging data, realizing classification and identification of logging data such as waveform features, frequency domain features and time domain features.

High-precision Fault Recognition

Construct a massive fault training sample library and use three-dimensional high-precision convolutional network technology to learn and predict fractures.

High-precision Layer Tracking And Interpretation

Using a small number of layer skeletons as a sample set, neural network technology is used to substantially improve the efficiency and accuracy of automatic layer tracking.

Reservoir Prediction

Using AI algorithms to predict and evaluate reservoirs involves tracking and forecasting the distribution, thickness, and lithology of the reservoirs.

Logging Physical Parameters Prediction

Based on machine learning theory, regression models can identify the nonlinear mapping relationship between logging data and formation petrophysical parameters, accurately predicting the variation of porosity in reservoir sections.

Logging Petrographic Categories Prediction

In order to establish the fuzzy rules between core porosity and petrophysical logging, extract the optimal parameters of fuzzy clustering, and propose a new algorithm for matching data from multiple logging curves.

Log Stratigraphy Delineation

A target mapping function from logging curves to lithofacies was established to predict the lithofacies corresponding to the uninterpreted logging data.

Drilling Solutions

Anton Drilling Industry Group is a leading provider of superior drilling and low-cost drilling technology, with services covering the entire drilling process and a series of key drilling technologies, featuring horizontal well drilling and integrated drilling and completion turnkey service model.

Drilling Geology Design

AI algorithm learns historical geological data and design information, and intelligently outputs more accurate geological design, providing better reference and risk warning for engineering design.

Drilling Engineering Design

Based on the learning of historical engineering data and design information, AI actively outputs more accurate engineering design to achieve drilling purposes safely, efficiently and quickly

Geological Risk Analysis

The neural network extracts potential features of faults, suppresses noise interference, and establishes a nonlinear mapping relationship from seismic data to target faults for rapid intervention.

Real-time Geosteering

AI automatically identifies feature data to judge the current layer position, which facilitates early intervention to arrange control measures, thus realizing precise geological guidance to improve the drilling encounter rate.

Risk Warning

Big data deep learning identifies engineering risk points and formulates countermeasures. It also sets risk thresholds in multiple dimensions and intervenes in advance to control and avoid complex accidents.

Parameter Real-time Optimization

Machine learning algorithm analyzes the relationship between data elements and drilling speed to obtain prediction, and outputs options and quantitative values for drilling parameter optimization according to the drilling speed prediction model.

Engineering Measures Optimization

Intelligent analysis of wellbore fluid, friction and other data to determine the downhole situation, optimize the paddle eye, short start-up and downhole measures under the premise of ensuring safety, and greatly reduce the drilling cycle.

Fracturing Solutions

Based on the integration of geology and engineering, the company has transformed from traditional empirical iterative fracturing to intelligent fracturing, provided intelligent fracturing technical services through cloud platform+ edge computing, fully explored the potential of massive historical data, improved the timeliness and pertinence of parameter optimization, maximized the control of fracturing risks, and enhanced the effect of fracturing reform.

Fracturing Parameters Optimization

Based on vast historical single-well data and big data models, we establish mapping relationships among geological parameters, engineering parameters, and EUR, enabling intelligent optimization of fracturing design parameters.

Drilling Engineering

Establish the mapping relationship between hidden engineering features and EUR based on the big model, clarify the optimal direction of one or several groups of key hidden engineering features, establish the mapping relationship between hidden engineering features and engineering parameters based on the big model, and optimize the construction parameters in real time according to the mapping relationship between hidden engineering features and EUR.

Oil & Gas Recovery Solutions

Anton Oil & Gas Services is a professional integrated service provider for oil&gas extraction, equipped with a high-quality and experienced team, specialized design software, and an international standard management system. The company integrates global oil extraction technologies to offer full lifecycle drainage and gas extraction process technical services, oilfield chemical products and technical services, artificial lift products and technologies, as well as oilfield operation and maintenance services, and specialized oil extraction technical services for domestic and international oilfields.

Oil & Gas Recovery Explained

By collecting a large number of low permeability oil wells water content data and measuring and recording wells static data, fracturing and reforming data, production parameters and other data to do normalized fitting processing, to get the low permeability oil wells water content rising law interpretation of the plate, to provide a theoretical basis for the production of low permeability wells water control.

Layer Injection Services

For water injection development blocks, the NSGA-III downhole intelligent measurement and control system is used for precise layer-by-layer injection and production. It collects real-time monitoring data such as downhole layer pressure, temperature, and flow of water injection well groups, inputs this data into the NSGA-III downhole intelligent measurement and control system brain, and intelligently outputs adjustments to the sizes of water and corresponding oil orifices. This precise optimization of the injection-to-production ratio maintains a balance between injection and production, reduces interlayer conflicts, minimizes ineffective water injection, and improves waterflooding efficiency. Concurrently, it optimizes the design of layer-by-layer injection and production through offline database and knowledge base data reading and fitting.

Formation Monitoring Solutions

Anton Deep Earth IntelliLight characterized by customization and systematization, offers data collection and interpretation services throughout the entire oil&gas development process. The business includes fiber optic monitoring technology, digital rock technology, reservoir monitoring technology, and logging technology.

Oilfield Asset Intelligence Services

Provide oil&gas enterprises with technologically independent and controllable equipment intelligent transformation solutions and oilfield intelligent management solutions with rich product lines, and provide reliable oil&gas production, storage and transportation, refining and chemical intelligent consulting and services based on profound oil&gas industry experience, and promote the comprehensive digital transformation of oil&gas asset management.

Intelligent Inspection Management Software

Committed to empowering through digital technology, building a smart, environmentally friendly, and safe digital application ecosystem around the entire lifecycle of assets, maximizing asset value, and assisting customers in the digital and intelligent management of their assets.

Smart Station Solutions

It provides all-round digitalized management of equipment, security and production processes in oil and gas stations.

It integrates various advanced technologies such as Internet of Things (IoT), big data analysis, artificial intelligence (AI), and automation equipment to comprehensively cover the equipment, inspection, security and production of the stations, and realize online management and real-time monitoring and warning functions. It is efficiently linked through AR and other visualization means to realize the development vision of intelligent oil and gas field with standardized operation, visualized production, integrated operation, collaborative research and lean management.

Smart Security Solutions

Create an all-weather comprehensive security system to reduce operational costs and ensure production safety. Antoni Digital Intelligence's smart security solution, from the perspective of oilfield QHSE management, focuses on oilfield security scenarios to build an integrated security system that replaces manual security with technical measures, ensuring convenient and efficient access, timely emergency response, and proactive real-time prevention. Antoni Digital Intelligence provides comprehensive management support and safety control, ensuring more convenient, accurate, and secure safety management with more timely responses.

Oil & Gas Production Intelligent Control Solutions

Automated collection of various types of data from wells and stations realizes real-time perception of oil and gas production dynamics and full-process monitoring of oil and gas processes.

Based on the automated collection of data from wells and stations and video monitoring, and making full use of cloud computing, big data and other new technologies, the solution realizes real-time sensing of oil and gas production dynamics, monitoring of the whole process of oil and gas production, and precise and efficient command of the operation, so as to meet the oil and gas production management requirements of comprehensive sensing, precise control, advanced warning, efficient coordination, intelligent optimization and scientific decision-making.

Intelligent Monitoring Solutions of Equipment and Facilities

Real-time monitoring of key equipment operation status, automatic anomaly alerts, and cost reduction for increased efficiency. Suitable for key equipment such as drilling, fracturing, and continuous tubing operations. The intelligent monitoring solution for equipment and facilities combines Industrial Internet of Things (IIoT) and Augmented Reality (AR) technology to monitor equipment operation in real-time, automatically notify of anomalies, significantly reduce downtime, enhance maintenance efficiency, and improve the success rate of first-time repairs, optimizing service processes. It is applicable to key equipment such as pumps, drilling, well repair, fracturing, and continuous tubing, helping enterprises to enhance management capabilities and reduce operational costs.

Process Big-data Analysis System Solutions

The process big data analysis system solution is specially designed for purification refineries with complex processes, deeply integrating big data, neural network algorithms and artificial intelligence technologies to realize precise tuning of process parameters, real-time early warning of equipment operation, effective management of energy saving and consumption reduction, multi-dimensional comparative analysis, and scientific decision-making support, which comprehensively help enterprises achieve efficient and stable production and operation.

Petroleum Engineering Remote Monitoring and Command Solution

This solution is dedicated to technology empowerment, enabling comprehensive data collection at the job site, real-time monitoring of equipment status and operation, and has integrated capabilities for real-time alarms, issue tracking, and predictive decision analysis. It creates an integrated management system for "people, machines, and materials" with automated data collection, intelligent risk identification, and informatized management processes. By ensuring safe and effective supervision, collaborative business execution, and accurate and reliable decision-making, it significantly enhances the management efficiency and user experience of oilfield projects.

Smart Pipeline Network Solutions

Based on GIS and BIM technology, smart pipe network solution combines with Internet of Things, big data, cloud computing and artificial intelligence to provide comprehensive pipe network operation and maintenance management. Taking “data integration, application integration, business linkage and intelligent management” as the core, it builds an integrated system of “map+model+data+business”, realizes digital, online and intelligent management of pipeline network, and solves the problems of poor visibility, difficult management, scattered data, etc. of traditional pipeline network, and improves the management efficiency and intelligent level of pipeline network. It solves the problems of poor visibility, difficult management and scattered data of traditional pipeline network, and improves the management efficiency and intelligence level of pipeline network.

Smart Oil & Gas Infrastructure Construction

Integrating advanced technologies with self-developed products, the smart oil and gas infrastructure construction provides comprehensive system integration and global operation and maintenance support, aiding the oil and gas industry in achieving efficient, safe, and sustainable development.

Full-scenario Digital O&M Services for Oil & Gas

Combining the requirements of ITSS/ITIL and other domestic and international management systems, we provide clients with customized and systematic professional accompanying operation and maintenance services according to the characteristics and management needs of the oil and gas industry to ensure that the requirements of SLA (Service Level Agreement) are met and the high reliability and stable operation of clients' information systems are guaranteed.

Promotional Videos

Offering specialized and customized video production services, including corporate videos, product videos, brand videos, investment promotion videos, and thematic videos.

3D Animation

Provides faster and more efficient 3D promotional animations for technology and services, including original animations, popular science videos, and technical concept videos.

Graphic Design

Providing a full range of design services including scientific illustrations, concept design, brand image design, and web design, aimed at meeting the customized promotional needs of industry clients. Services include brand image design, web/UI design, cultural and creative products, gift design, live broadcasting, exhibition, and event planning.

AI Application Training For All Employees

Provide comprehensive AI technology training services for your company to enhance employees' skills in using general AI tools. Staff can leverage open, online large-model AI to assist in various application scenarios, improving operational efficiency. This includes AI tools for PPT creation, image editing, promotional graphic generation, AI video production, virtual digital human creation, and code editing.

Enterprise AI Transformation Consulting

Develop AI transformation planning for your organization, sort out AI transformation scenarios, and assist in the full implementation of AI transformation.

Oil & Gas Enterprise Large Model Cloud Platform Planning And Construction Services

Anton integrates computing power and foundational models, leveraging its understanding of the oil and gas industry and artificial intelligence modeling capabilities to provide overall planning, consultation, design, and construction for large model platforms.

Business GPTs Project Services

Based on the user's existing AI training platform and data, Anton provides full-scenario AI project delivery services for oil and gas development, including model development, inference compression to application development process.

Oil & Gas Company Data (Knowledge) Governance Services

Anton combines the capabilities of data governance service providers to achieve data cleansing, feature selection and data annotation, ultimately improving the usability of user data and maximizing the effect of artificial intelligence models. Local data provided by the client is used as the model base database to maximize the effect of the AI model.

Basic Computing Power Optimization Services

Anton provides computing power optimization and adaptation services based on specific scenario requirements of users, in conjunction with the technical specifications of computing power service providers and basic large model manufacturers, to maximize the effectiveness and value of large models and computing power.

Anvision

What does Anvision do?

Based on various application scenarios in oil&gas fields, Anvision provides professional accompanying services with the most reliable project landing, the fastest project cycle, and the lowest cost to meet the rigid demand for digital intelligence in oil and gas fields. Our services include comprehensive solutions for smart oilfields, oil and gas field full-scene digital intelligence services, and artificial intelligence solutions for the oil and gas industry, which help enterprises realize digital transformation and intelligent upgrading.

What services does Anvision provide?

Based on various application scenarios in oil&gas fields, Anvision provides professional accompanying services with the most reliable project landing, the fastest project cycle, and the lowest cost to meet the rigid demand for digital intelligence in oil and gas fields. Our services include comprehensive solutions for smart oilfields, oil and gas field full-scene digital intelligence services, and artificial intelligence solutions for the oil and gas industry, which help enterprises realize digital transformation and intelligent upgrading.

Oil Mates Multimedia Services

Oil Mates Multimedia is committed to providing multimedia services for the oil and gas industry, making the oil and gas world more audible and stylish. Our services cover video promo production, 3D animation production, poster graphic design and so on.

Oil & Gas Generic AI Cloud Platform

What does Oil & Gas Generic AI Cloud Platform work for? What is offered on the Oil & Gas Generic AI Cloud Platform? What products or services are available?

The platform covers oil and gas industry information GPTs, oil and gas scenario GPT application development services, enterprise operation efficiency GPTs, office assistance efficiency GPTs, auxiliary field construction GPTs, digital intelligent oilfield full-scene GPT applications, intelligent multimedia, AI training and transformation information, enterprise self-built GPT cloud platform and other sections of services. Adhering to the service to all parties in the oil and gas industry, so that the oilfield digital intelligence is simple and easy to implement.

Positioning of Oil & Gas Generic AI Cloud Platform

Oil & Gas Generic AI is a professional and open AI cloud platform for the global oil and gas industry, which allows people in the global oil and gas industry to conveniently access professional AI services and helps the industry's intelligent transformation.

Intelligent Geological Stratification Analysis

Intelligent Geological Stratification Analysis business pain points and challenges:

1.Traditional drilling relies on human experience and surface data, making it difficult to achieve real-time analysis and response to complex subterranean formations. The intelligent drilling platform optimizes drilling paths through real-time data analysis and intelligent decision-making, thereby improving drilling efficiency and reservoir penetration rates.

2.Non-productive time (NPT) and unexpected events during drilling can increase costs. The intelligent drilling platform reduces NPT, accelerates real-time decision-making, and improves decision accuracy through prediction and real-time monitoring, thereby lowering overall drilling costs.

3.Drilling operations are high-risk, and relying on manual monitoring and response may result in safety vulnerabilities. The intelligent drilling platform can monitor subsurface data in real-time, intelligently identify risks and issue early warnings, thereby improving operational safety.

Intelligent Prediction Of Estimated Ultimate Recovery (EUR)

Estimated Ultimate Recovery (EUR) pain points and challenges:

1.The management of geological and project engineering data poses significant challenges, resulting in inefficient information integration and application.

2.Traditional fracturing prediction methods are relatively inefficient and unable to respond quickly to market changes, thereby affecting project progress.

3.The limited and non-replicable engineering expertise of experts leads to difficulties in knowledge transfer, impacting the overall effectiveness of the team.

Drilling Construction Parameter Generation

Drilling Construction Parameter Generation pain points and challenges:

1.The selection of drilling parameters mainly relies on engineers' personal experience, lacking scientific and systematic data analysis, which leads to inaccurate decisions and affects drilling efficiency and safety.

2.With changes in blocks and formations, traditional drilling parameters need to be re-explored and adjusted, which is not only time-consuming and laborious but also significantly affects drilling speed and timeliness, increasing operational costs.

Formation Pressure Anomaly Alarm

Formation Pressure Anomaly Alarm pain points and challenges:

1.Formation pressure is crucial in drilling engineering design, but if abnormal high or low pressure is not predicted in a timely manner, it can easily lead to well control hazards or lost circulation, jeopardizing drilling safety, increasing operational risks, and causing unnecessary economic losses.

2.The lack of scientific basis for selecting drilling parameters makes it difficult to flexibly respond to changes in formation pressure, resulting in frequent adjustments to parameters during the drilling process, which affects drilling efficiency and may even trigger safety accidents and delay the schedule.

Sand Plugging Alarm

Sand Plugging Alarm pain points and challenges:

1.Missed and false alarms can lead enterprises to miss the optimal timing in addressing sand blockage issues, thereby increasing maintenance costs and the risk of production shutdowns, which in turn affect overall operational efficiency and customer satisfaction.

2.The accuracy of predictions decreases under different wellbore or operating conditions, and the frequent need for adjustments and optimizations increases the consumption of human resources, affecting the progress of other business operations.

3.The integration of information from various sensors and data sources is complex, leading to data isolation, which affects overall business decision-making and coordination efficiency, limiting the enterprise's ability to respond flexibly.

Fiber Optic Wellbore Leakage Point Real-time Prediction

Fiber Optic Wellbore Leakage Point Real-time Prediction pain points and challenges:

1.Fiber-optic sensors are susceptible to external interference, which may result in inaccurate data acquisition, further impacting the reliability of leakage point predictions and increasing potential risks.

2.Delays in the transmission and processing of fiber-optic monitoring data can lead to untimely leakage point predictions, thereby affecting the company's decision-making and response speed in addressing leakage points.

3.Due to the high demands for maintenance and updates of the fiber-optic monitoring system, companies face challenges in resource allocation, which can hinder overall operational efficiency and cause delays in the progress of other projects.

Smart Station Solutions

Smart Station Solutions pain points and challenges:

1.Because a number of equipment types and different brands, accessing and management are complicated.

2.Operational procedures often rely on manual operations and empirical judgments, not only ineffective but also high error rate.

3.Traditional station maintenance activities require extensive manual inspections, which not only increases labor costs but also lead to equipment failures or safety accidents due to untimely inspections or inadequate maintenance.

4.Data island often exists between different devices and systems, preventing data from being effectively shared and utilized.

Smart Security Solutions

Smart Security Solutions pain points and challenges:

1.There are monitoring blind spots, resulting important areas monitoring useless.

2.It relies heavily on manual patrols and inspections, it is inefficiency and prone to errors; only provide simple video surveillance and lacks intelligent analysis capabilities.

3.Traditional security systems often take a long time to respond after detecting abnormal situations.

Petroleum Engineering Remote Monitoring and Command Solution

Petroleum Engineering Remote Monitoring and Command Solution pain points and challenges:

1.Monitoring blind spots, making it difficult to respond to emergencies in real-time:The complex and ever-changing operating environment of petroleum engineering makes it challenging for traditional monitoring methods to achieve comprehensive coverage, resulting in an inability to grasp the operational status in real-time and promptly respond to emergencies.

2.Data islands, lacking efficient integration and analysis:Petroleum engineering involves a vast amount of data, with severe data island phenomena among various business systems. The lack of effective data integration and analysis methods impacts decision-making efficiency and quality.

3.Difficult safety management, inadequate hidden danger prevention and control capabilities:The difficulty of on-site safety management is significant, with potential safety hazards such as oil spills and illegal intrusions. Intelligent technology is needed to enhance safety management levels and emergency response capabilities.

Oil & Gas Production Intelligent Control Solutions

Oil & Gas Production Intelligent Control Solutions pain points and challenges:

1.Inadequate Data Collection:The traditional data collection method is inefficient, making it difficult to achieve real-time monitoring and affecting production decisions.

2.Difficulties in Equipment Management:Frequent failures encountered during equipment maintenance, coupled with the inability to implement real-time monitoring and early warning for critical equipment, impact production efficiency.

3.Untimely Emergency Response:Slow reaction in response to emergencies, inability to quickly identify risks, and lack of effective emergency response plans.

Intelligent Monitoring Solutions of Equipment and Facilities

Intelligent Monitoring Solutions of Equipment and Facilities pain points and challenges:

1.Inadequate early warning for equipment failures leads to unplanned shutdowns and increased maintenance costs.

2.Inefficient manual inspections fail to comprehensively cover all monitoring points, affecting the timeliness of equipment maintenance.

3.The dispersion of equipment operation and maintenance data, coupled with the lack of effective data analysis tools, results in low levels of equipment health management.

Process Big-data Analysis System Solutions

Process Big-data Analysis System Solutions pain points and challenges:

1.Data Island and Information Sharing Challenges:Because it is inability to integrate and share data between different systems and devices, so result in data island.

2.Varying Data Quality:Data generated during production may be missing, incorrect, or inconsistent, directly effecting accuracy and reliability of data analysis.

3.Complexity and Uncertainty Process Procedures:Industrial production processes involve multiple stages and factors, with complex and variable process flows and uncertainties.

4.Inadequate Decision Support:Due to insufficient data integration, lack analytical tools or analysis depth, it is impossible to provide adequate decision support for management.

Smart Pipeline Network Solutions

Smart Pipeline Network Solutions pain points and challenges:

1.Pipeline network monitoring technology has gradually been strengthened, but there are still deficiencies in the application of data and analysis technologies.

2.The aging of pipeline networks and prominent safety hazards affect normal supply services and may lead to safety accidents.

3.The content of operation and maintenance management is complex, with heavy workloads for manual management and record-keeping, resulting in low work efficiency.

Smart Oil & Gas Infrastructure Construction

Smart Oil & Gas Infrastructure Construction pain points and challenges:

1.The high degree of encapsulation in automation systems makes it difficult to achieve unified management and precise control across different systems.

2.The lack of effective data asset management results in a heavy reliance on personnel for inefficient searching and analysis.

Full-scenario Digital O&M Services for Oil & Gas

Full-scenario Digital O&M Services for Oil & Gas pain points and challenges:

1.Decentralized Resource Management:Internal resources are scattered, making it difficult to focus on core business, which leads to inefficiency.

2.Lagging Fault Response:Traditional IT companies are slow in handling equipment failures and emergencies, affecting the operation of core businesses.

3.Data Security Risks:Unreliable data backup and recovery pose risks of losing or leaking important information.

Intelligent Gas Storage Solutions

Intelligent Gas Storage Solutions pain points and challenges:

1.Complexity of Equipment Management:The diverse range of process equipment in gas storage facilities is complex to maintain and prone to faults during prolonged operation, leading to economic losses and potential safety hazards.

2.Uneven Distribution of Construction Resources:High-quality resources for gas storage facility construction are scarce and unevenly distributed, resulting in high construction costs and low operational efficiency.

3.Inadequate Intelligence Level:The current level of informatization in existing gas storage facilities is still in its early stages, unable to meet the future development needs for intelligent and smart gas storage facilities.

Smart Training and Emergency Simulation Platform

Smart Training and Emergency Simulation Platform business pain points and challenges:

1.Difficulty in Practical Drills:Traditional training methods struggle to simulate real and complex scenarios, leading to employees lacking practical operational experience in emergency situations.

2.High Training Costs:Organizing offline emergency drills requires significant human and material resources, and they cannot be conducted frequently, resulting in a waste of resources.

3.Difficulty in Quantifying Training Effects:The lack of effective evaluation tools and methods makes it impossible to accurately measure the effectiveness of training, making it challenging to ensure the quality of training.

Smart Station Solutions

Smart Station Solutions pain business pain points and challenges:

1.Difficulty in integrating technology with business:The Oil & Gas industry is highly specialized with complex business processes, requiring deep integration of artificial intelligence technology with industry knowledge. However, there exists a communication barrier between algorithm engineers and business personnel, making it difficult to form effective technical solutions.

2.Challenge of iterative upgrades for intelligent applications:Intelligent applications in the Oil & Gas industry require continuous technological iteration and funding. However, current technologies and methodologies are still immature, lacking sustained upgrades and financial support, which hinders the continuous optimization and expansion of these intelligent applications.

Enterprise Management Knowledge GPT Development Services

Enterprise Management Knowledge GPT Development Services business pain points and challenges:

1.Dispersed Knowledge Achievements and Relatively Difficult Integration:Knowledge achievements within the enterprise are scattered and not effectively integrated and uniformly managed, which is not convenient for knowledge sharing and efficient application.

2.Difficult Knowledge Inheritance:There is no effective knowledge inheritance mechanism. When there are personnel changes, a large amount of knowledge and experience is lost.

3.Lack of an Atmosphere for Knowledge Innovation:There is no knowledge application platform. Employees lack the motivation for knowledge innovation, making it difficult to stimulate new business ideas.

Enterprise Management Digital Intelligence Overall Solution Services

Enterprise Management Digital Intelligence Overall Solution Services business pain points and challenges:

1.Lack of Overall Planning Ability:The enterprise itself lacks professional and technical talents and cannot accurately assess the input-output ratio of digital intelligence. The current situation and planning are not clear, and decisions lack scientific basis.

2.High Implementation Risk:There is no relevant implementation experience, and the selection and technical evaluation are insufficient, resulting in high project costs and a long entire cycle.

Data-driven Intelligent Decision-making Platform Design and Construction Services

Data-driven Intelligent Decision-making Platform Design and Construction Services business pain points and challenges:

1.There are numerous enterprise business systems, and business data is scattered. The phenomenon of data silos is widespread, and data is not well shared and applied.

2.Business data in various fields of the enterprise is not systematically managed. The data management process is unclear, standards are not unified, there is a lack of systems, and data security measures are not in place.

3.Data statistics and summarization take a long time, and data timeliness is insufficient, affecting the timeliness of decision-making.

4.Data analysis and application are insufficient. Massive business data cannot be fully analyzed and mined. Data application scenarios are limited, and the value of data is not maximized.

Smart Employee Community Design and Construction Services

Smart Employee Community Design and Construction Services business pain points and challenges:

1.There is a lack of a community-based interaction platform within the enterprise,information transmission overly relies on traditional hierarchical channels, resulting in untimely internal communication, collaboration, and information transfer.

2.There are numerous enterprise business systems,employees need to switch between multiple systems when working. There is no unified platform entrance, and cross-platform collaboration efficiency is low.

3.Enterprise teamwork and cohesion are weak,internal information is opaque. Organizational activity cannot be better mobilized. A learning atmosphere of sharing and co-creation has not been formed within the organization. Collective wisdom has not been able to empower enterprise innovation well.

Smart E-commerce Platform Design, Construction and Operation Services

Smart E-commerce Platform Design, Construction and Operation Services business pain points and challenges:

1.Traditional marketing and sales channels face problems such as geographical and customer group limitations. The forms of market coverage and customer access and acquisition are relatively single.

2.Establishing and maintaining traditional sales channels requires a large amount of capital and human cost investment. Channel management is complex and it is impossible to master sales situations in real time.

3.Brand dissemination is limited and it is difficult to shape the brand image. It is impossible to understand customer needs and feedback in a timely manner.

Management Process Automation Platform Design and Construction Services

Management Process Automation Platform Design and Construction Services business pain points and challenges:

1.Low Process Flow Efficiency:Traditional approval processes are complex. Multi-node approvals take a long time and there is no automatic approval, which is prone to delays and affects the rapid response of business.

2.Lack of Process Transparency:Traditional processes lack transparency. Relevant positions find it difficult to monitor process progress and problems in real time, affecting management decisions.

3.Lack of Process Compliance Review:Manual approvals are affected by human factors and lack objective data support. The risk of errors is high and it is easy to lead to compliance risks.

Intelligent Drilling Solutions

Intelligent Drilling Solutions business pain points and challenges:

1.Insufficient Geological Prediction:Traditional drilling relies on manual interpretation of geological data, resulting in limited accuracy of geological models and thereby increasing the uncertainty and risk in the drilling process.

2.Insufficient Risk Management:The identification of engineering risk points and response measures often rely on experience, which makes risk assessment lack systematicness and forward-looking nature and makes it difficult to respond to emergencies in a timely manner.

3.Difficulty in Optimizing Drilling Parameters:Optimizing drilling parameters usually requires a large number of tests and adjustments, which not only takes time but also greatly increases the overall cost of the project.

4.Insufficient Intelligence in Engineering Measures:Traditional optimization of engineering measures relies on manual judgment, resulting in slow response speed and insufficient accuracy, which in turn affects the overall drilling efficiency and safety.

Intelligent Fracturing Solutions

Intelligent Fracturing Solutions business pain points and challenges:

1.The Risk of Sand Plugging is Difficult to Predict in Advance:In fracturing operations, it is difficult to predict the risk of sand plugging in advance, which may lead to construction failure, production interruption or well loss.

2.The Prediction of EUR Production is Inaccurate:It is impossible to accurately predict the EUR production in the same well area, affecting the return on investment and the rationality of the development plan.

3.It is Difficult to Select Fracturing Construction Parameters:Due to the complex geological conditions in different well areas, the selection of fracturing construction parameters relies on experience or multiple tests, increasing time and resource costs.

Formation Monitoring Solutions

Formation Monitoring Solutions business pain points and challenges:

1.Lack of Real-time and Accurate Wellbore Data:Key data such as temperature, pressure, and sound waves cannot be obtained in a timely manner, making it difficult to respond to downhole changes promptly.

2.Leakage Points are Difficult to be Detected and Accurately Located in a Timely Manner:This increases safety and environmental risks and affects maintenance efficiency and cost control.

3.Wellbore Integrity Risks are Difficult to Monitor:It affects safety and operation and makes it impossible to detect problems such as wellbore leakage and structural damage in a timely manner.

4.Lack of Intelligent Analysis Tools:It is difficult to extract valuable insights from a large amount of data, and it is impossible to optimize the production system, resulting in low recovery factor.

5.High Maintenance and Operation Costs:Problems cannot be found and dealt with in a timely manner, resulting in increased maintenance costs and downtime.

6.Traditional Monitoring Methods are Insufficient:Unable to meet the monitoring needs of efficient, safe, and intelligent Oil & Gas production, affecting the overall operational efficiency.

Equipment And Facility Monitoring Solutions

Equipment And Facility Monitoring Solutions business pain points and challenges:

1.Pain Points in Equipment Management:Dispersed systems lead to complex management and low efficiency. Traditional maintenance methods are backward and cannot predict equipment failures, increasing downtime and maintenance costs. Lack of comprehensive equipment health monitoring makes it difficult to prevent problems in a timely manner.

2.Pain Points in Production Monitoring:Lack of real-time production data leads to delayed decision-making. Insufficient data analysis capabilities make it impossible to predict production trends and production efficiency. Inadequate emergency response increases risks.

3.Pain Points in Asset Management:Incomplete asset management cannot achieve maximum value. Insufficient environmental protection and safety management. Low degree of digitization cannot support intelligent decision-making and affects operational efficiency and compliance.

4.Pain Points in Comprehensive Management:Information silos and lack of a unified platform to integrate various functions. Lack of intelligent and digital support affects the digital transformation of enterprises. Unable to comprehensively improve management efficiency and operational optimization.

AI Application Training For All Employees

AI Application Training For All Employees business pain points and challenges:

1.Lack of understanding of new technologies,enterprises cannot accurately identify the combination scenarios of AI application tools and their own businesses.

2.Difficult to formulate targeted and practical training content,the formulation of training organization, assessment and evaluation lacks scientificity, and the training results cannot be effectively evaluated.

Enterprise AI Transformation Consulting

Enterprise AI Transformation Consulting business pain points and challenges:

1.Lack of professional talents,the business complexity cannot be fully grasped. The formulated transformation plan does not match the business needs of the enterprise, and the work lacks a system.

2.Difficult to accurately assess the scheme planning:It is difficult to accurately assess the scheme planning and technical risks, and the project implementation and effect evaluation face great challenges.

Oil & Gas Enterprise Large Model Cloud Platform Planning And Construction Services

Oil & Gas Enterprise Large Model Cloud Platform Planning And Construction Services business pain points and challenges:

1.The technical threshold is high,the construction of a large-model cloud platform involves many technical fields and requires the enterprise itself to have strong research and development capabilities.

2.Lack of professional talents,it is difficult to gain insight into scenarios, and there are great challenges in integrating scenario applications with business.

3.The construction of a cloud platform requires a large amount of resource investment, with high costs, a long cycle, and it is difficult for results to appear quickly.

Business GPTs Project Services

Business GPTs Project Services business pain points and challenges:

1.Lack of Algorithm Experience Accumulation:The development of AI applications requires advanced algorithms and model support. Enterprises often lack experience and technical accumulation in algorithm research and development.

2.Lack of Algorithm Experience Accumulation:The development of AI applications requires advanced algorithms and model support. Enterprises often lack experience and technical accumulation in algorithm research and development.

Oil & Gas Company Data (Knowledge) Governance Services

Oil & Gas Company Data (Knowledge) Governance Services business pain points and challenges:

1.Lack of enterprise-level data governance top-level design,lack of resource coordination. Insufficient understanding of its value, with activities staying local.

2.Ununified internal data standards,prominent data silos in various fields. Data value not effectively mined and empowered to business.

3.Diversified internal enterprise data,enterprise internal data shows a trend of diversification and variety. Data cleaning and data annotation are difficult, which is not conducive to the integration of enterprise business data and artificial intelligence technology.

Basic Computing Power Optimization Services

Basic Computing Power Optimization Services pain points and challenges:

1.Low computing power resource utilization efficiency,high infrastructure costs, improper allocation and insufficient model training cause waste.

2.Lack of professionals for computing power optimization hampers effective promotion.

Service Feedback

Question: I have some suggestions and comments I need to give feedback on, how do I give feedback on issues? How do I give feedback on product and service related issues?

Answer: Your feedback is invaluable to us. During your experience with our products and services, you can give us feedback whether you are satisfied or there is room for improvement. This not only helps us better understand your needs, but also allows us to adjust and optimize in time to provide you with better products and services.

Contact Information

How to contact us

How can I get in touch with you?

We can be contacted in the following ways

Telephone: +86 18329773790

Email: service@oilgasgpts.com

You can also contact us through the online real-time customer service on the right side of the platform of this website.

Top

Feed-

back

back

Intelligent production control

Full process monitoring of oil and gas development, real-time perception of oil and gas production

dynamics, achieving intelligent oilfield management and control

Oil & Gas Digitalization, Simple and Practical

Product Inquiry

Product Introduction

Relying on integrated and intelligent technologies, a comprehensive management system for smart oilfields is constructed, covering core businesses such as production operations, equipment management, and reservoir development. Through real-time data collection and intelligent analysis, it achieves refined management of well monitoring, oil and gas management, equipment inspection, and reservoir data, optimizing decision-making and improving efficiency and safety. It assists oilfield enterprises in moving towards intelligent and refined operations.

Your Benefits

Real-time Data Control and Analysis

By collecting real-time data and utilizing intelligent analysis, customers can always grasp the production status of the oilfield, optimize production efficiency through data-driven decision-making, reduce operational risks, and promptly identify and resolve potential issues.

Efficient Equipment Management and Maintenance

The system supports the scheduling of equipment maintenance tasks, inspection management, and key equipment tracking, helping customers promptly identify equipment issues and perform preventive maintenance, thereby reducing equipment failures and downtime, and improving production continuity.

Flexible Terminal Access

Supports various terminal devices, allowing users to remotely view data, perform operations, and receive alerts at any time, improving work efficiency and management convenience.

Full Process Management of Oil and Gas Development

covers the entire process of reservoir development, production operations, and equipment management, helping clients achieve data integration and collaboration, enhancing transparency and efficiency in management.

Business Pain Points and Challenges

Insufficient Real-Time Data Processing and Analysis

Data collection is not comprehensive, and there is a lack of real-time analysis, making it difficult for enterprises to accurately grasp the production status of the oilfield.

Insufficient data sharing in oilfield production management

Oilfield production data is scattered, and there is a lack of collaborative management across different stages. Production operations, equipment facilities, and other data are stored in different systems, lacking unified integration.

The management of oilfield equipment is complex

There are various types of oilfield equipment, operating in harsh environments, with insufficient inspection and maintenance management, which increases the risk of production interruptions and affects overall production efficiency.

Insufficient data analysis and early warning

The amount of data generated by equipment and systems is vast and complex, lacking efficient analysis and early warning mechanisms. Manual analysis struggles to timely identify potential production issues or equipment failures, resulting in slow response times.

Core Functions

Production and operation

Oil well monitoring

Real time monitoring of oil well casing pressure, temperature, production and other indicators, and comprehensive analysis of multiple parameters. Integrated monitoring

Comprehensive monitoring of oil and gas metering and oil and gas processing station equipment and facilities, and generation of multi-dimensional analysis reports. production report

Automated generation and confirmation of full process reports to improve data accuracy and management efficiency.

Real time monitoring of oil well casing pressure, temperature, production and other indicators, and comprehensive analysis of multiple parameters.

Comprehensive monitoring of oil and gas metering and oil and gas processing station equipment and facilities, and generation of multi-dimensional analysis reports.

Automated generation and confirmation of full process reports to improve data accuracy and management efficiency.

Reservoir development

Reservoir information collection

Collect and record key indicators such as ESP operating parameters, well formation information, well coring data, well trajectory data, and logging data while drilling, providing accurate and reliable basic support for data analysis. Oil reservoir production analysis

From oil fields, oil regions to oil wells, multi-level and multi-dimensional production operation and reservoir development analysis reports provide comprehensive insights into development dynamics and assist in refined management.

Collect and record key indicators such as ESP operating parameters, well formation information, well coring data, well trajectory data, and logging data while drilling, providing accurate and reliable basic support for data analysis.

From oil fields, oil regions to oil wells, multi-level and multi-dimensional production operation and reservoir development analysis reports provide comprehensive insights into development dynamics and assist in refined management.

Equipment management

Equipment Overview

The system clearly displays the periodic arrangement of equipment and comprehensively controls the health status of the equipment. Maintenance management

Flexible configuration of equipment regular maintenance plan, intelligent warning and automatic generation of maintenance work orders, multi-dimensional presentation of the execution progress of maintenance tasks Comprehensive query

Provide multi-dimensional report queries to assist in intelligent operation and maintenance, achieving precision and visualization of equipment management.

The system clearly displays the periodic arrangement of equipment and comprehensively controls the health status of the equipment.

Flexible configuration of equipment regular maintenance plan, intelligent warning and automatic generation of maintenance work orders, multi-dimensional presentation of the execution progress of maintenance tasks

Provide multi-dimensional report queries to assist in intelligent operation and maintenance, achieving precision and visualization of equipment management.

Successful Cases

Intelligent Production Control

Intelligent Production Control

Oil & Gas Generic AI Community

AI Technology Seminar

Large Model Knowledge Base

Contact Us

Contact Us:Product Inquiry

Contact Email:anvision@anvision.com.cn

Contact Phone:+86 17521198294

Privacy Policy

Mobile Terminal

WeChat

No. 11 Yingbin South Road, Huairou District, Beijing

|Copyright Beijing Anvision Oil & Gas Generic Intelligent Technology Co., Ltd

|